APPLICATIONS

We work mainly with FPDs (Flat Panel Displays) to measure different features -arrays, coatings, or spacers- depending on which stage of the manufacture the characterization is performed.

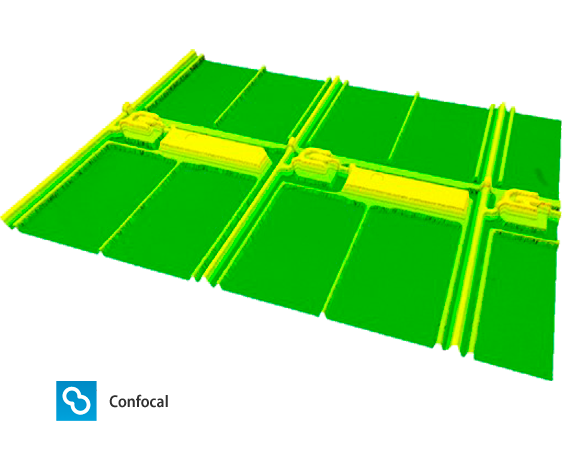

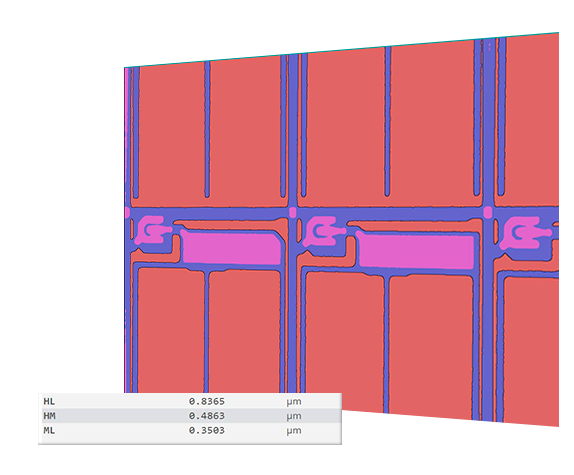

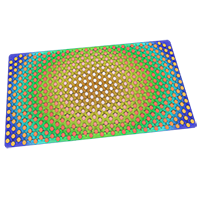

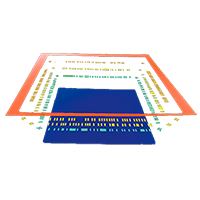

TFT Array in LCD

There is a method of making LCDs (Liquid Crystal Displays) that improves the contrast and speed of the display. It is called TFT (Thin Film Transistor) technology. TFTs are fabricated by means of photolithography and it is vital to know the height of each of the layers.

The Multiple Step Height plugin detects 3 different heights and groups the areas of the topography on the belonging height level. In this case, each of the levels detected is a layer deposited to make the TFT array.

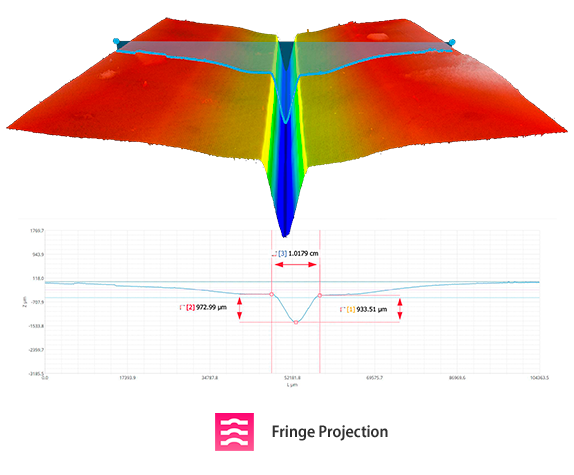

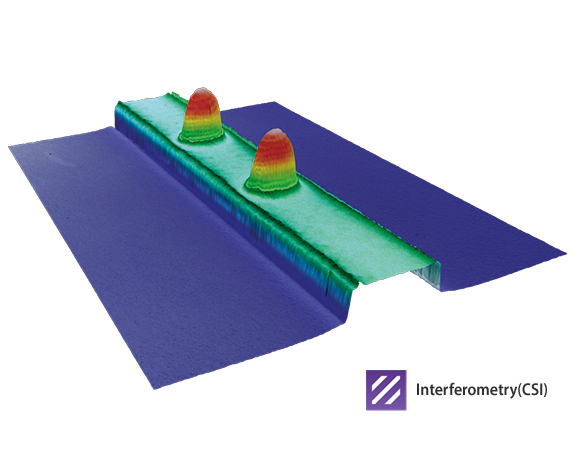

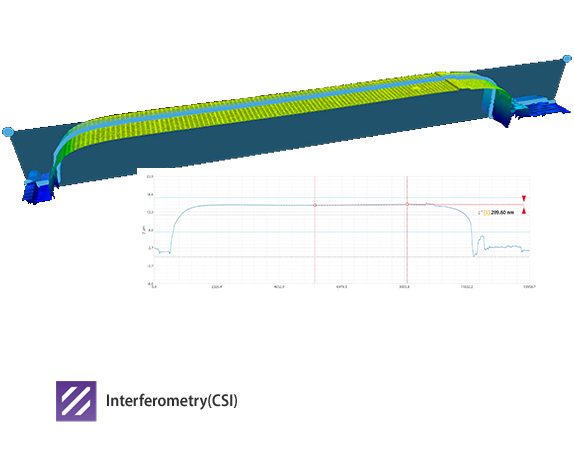

Foldable

smartphone

The latest smartphones and tablets are starting to incorporate flexible screens that can be folded. Our S wide is used by screen manufacturers to characterize the depth and width of the foldable area. In this example, we have used 4×4 stitching.

Critical dimensions on profile are allowed with this powerful analysis software.

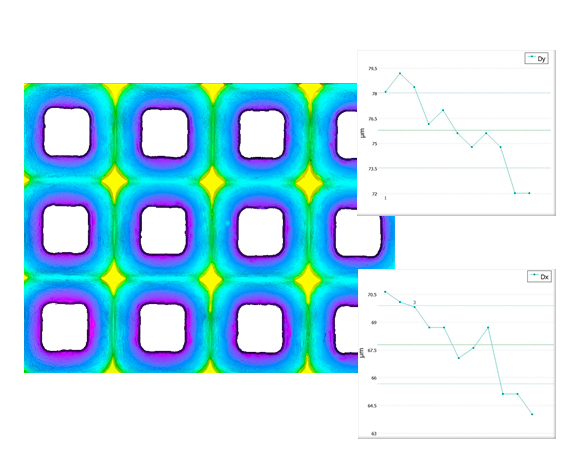

Trends in a data set can be easily spotted with the automatically generated graphs from data acquired during the analysis with the Rectangular Hole plugin.

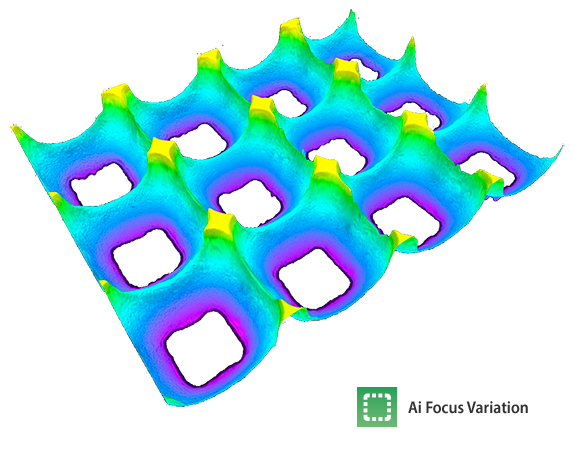

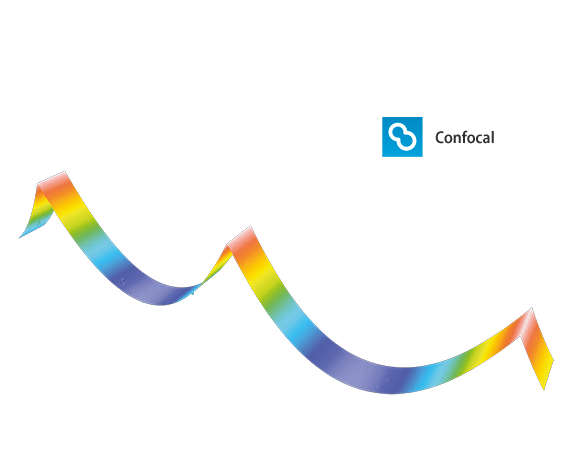

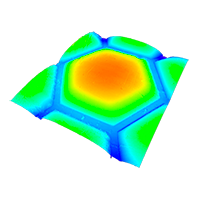

FPD-Coating Tendency

Several coatings are applied during photolithography when manufacturing a display. Often one needs to understand the uniformity of the coating through the structures.

This analysis software is an excellent tool for selecting a profile (in any direction) and doing some manual verification. The image shows the coating flatness on the top of the structure being checked.

This analysis software is an excellent tool for selecting a profile (in any direction) and doing some manual verification. The image shows the coating flatness on the top of the structure being checked.