Complete accessibility

The S neox Five Axis 3D Optical profiler combines a high-accuracy rotational module with the advanced inspection and analysis capabilities of the S neox 3D optical profiler. This enables automatic 3D surface measurements at defined positions which can be combined to create a complete 3D volumetric measurement.

MEASURING TECHNOLOGIES

Cover a wide range of scales

S neox 3D measurement technologies cover a wide range of scales, including form (Ai Focus Variation), sub nanometric roughness (Interferometry) or critical dimensions that require high lateral resolution as well as vertical resolution (Confocal).

MEASURING TECHNOLOGIES

Maximum versatility

The Five Axis system makes it possible to take automatic 3D surface measurements at defined positions, and combine them to create a complete 3D volumetric measurement or to inspect the surface finish at specific positions around the sample.

MEASURING TECHNOLOGIES

A complete 3D measurement

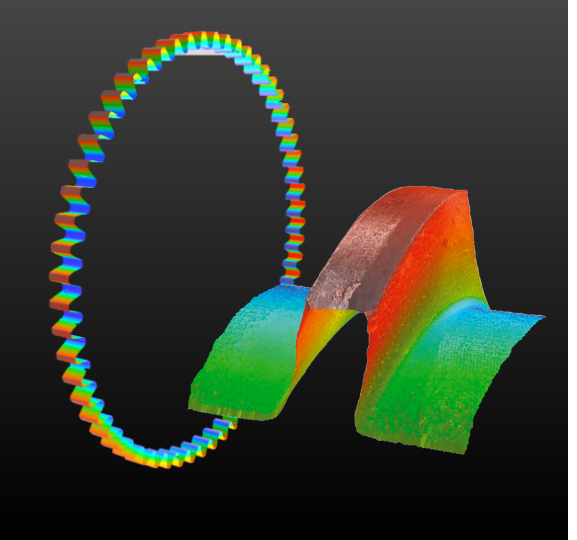

S neox Five Axis can measure the sample at different positions of rotation and elevation (perspectives), generating a group of individual measurements. The SensoFIVE software merges all of the surfaces providing a sample surface with high accuracy by using the stacked image information of each single surface measurement. The system can provide shape and form information on sharp edges and/or critical surfaces by merging different elevations.

Check out this video, showing how a cylinder would be measured

CONNECTING ADJOINING SURFACES

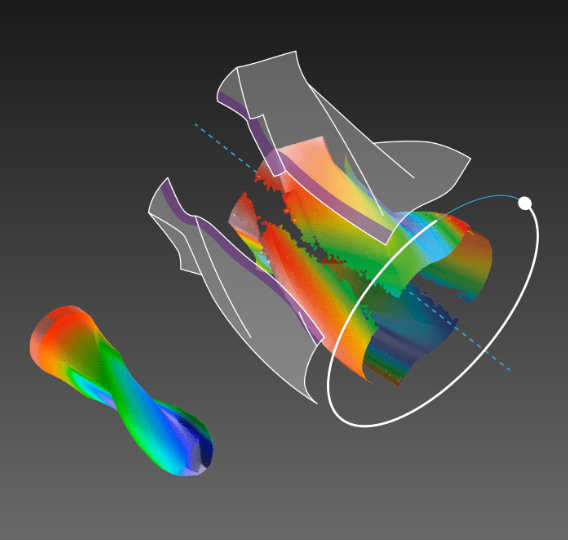

Measure angles greater than 90º

Measuring complex surfaces which contain steep angles is very difficult due to shadowing effects that prevent you from obtaining a complete measurement within a single acquisition. It is necessary to tilt the sample to measure it from two different positions and combine the two topography results to obtain the complete measurement. Five Axis rotational stage allows the sample to be positioned in opposite directions to make the entire surface visible. The 3D optical profiler will acquire the individual measurements, and then it will merge them automatically to get the complete 3D volumetric measurement.

Check out this video, showing how to obtain a full 3D measurement

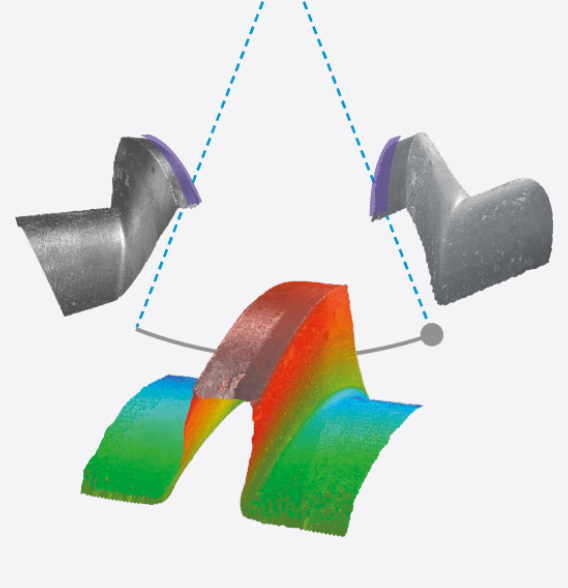

MULTIPLE AXIS POSITIONS

Measurements without limitation

Measuring different parts of the sample with one click is possible thanks to automation routines. A user-friendly interface allows you to find the measurement position without any constraints. Then focus on the critical parts of your sample and add them to the automation routine. Finally click Acquire to obtain all parts measured with one single click. This is an incredibly fast and easy way to automate the measurement routines.

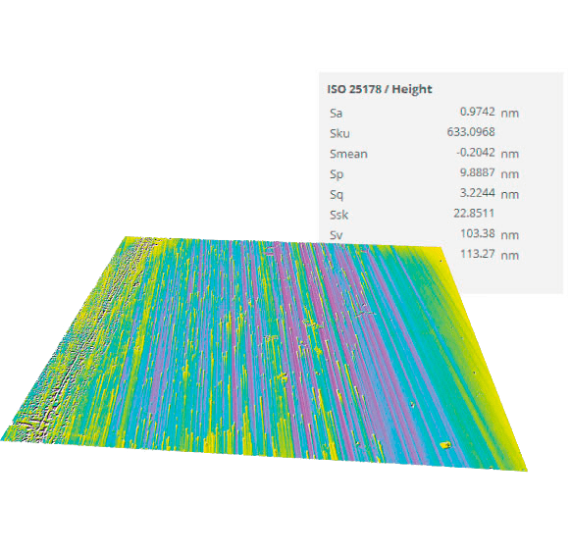

SURFACE FINISH MEASUREMENTS

Accurate and reliable

Our Confocal and Interferometry technologies allow you to measure surfaces with any kind of roughness from extremely rough (typical of additive manufacturing applications) to highly reflective surfaces of the order of 1 A as a diamond mirror-like surface. Converting our 3D optical profiler into repetitive and traceable, according to NPL, NIST and PTB roughness standards. Ai Focus Variation technology provides an easy and quick response for measuring outstanding slopes independently of the objective lenses.