Confocal unrolled areal measurements of cylindrical surfaces

Confocal unrolled areal measurements of cylindrical surfaces full article

A. Matilla,1 C. Bermudez,1 J. Mariné,1 D. Martínez,1 C. Cadevall,2 R. Artigas2

1 Sensofar-Tech, S.L. (Spain)

2 Universitat Politècnica de Catalunya (UPC) Rambla Sant Nebridi, 10, E-08222 Terrassa, Spain

Proceedings Volume 10329, Optical Measurement Systems for Industrial Inspection X; 1032915 (2017)

Event: SPIE Optical Metrology, 2017, Munich, Germany

Abstract

Confocal microscopes are widely used for areal measurements thanks to its good height resolution and the capability to measure high local slopes. For the measurement of large areas while keeping few nm of system noise, it is needed to use high numerical aperture objectives, move the sample in the XY plane and stitch several fields together to cover the required surface.

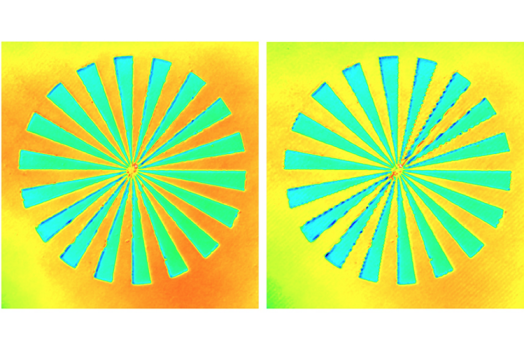

On cylindrical surfaces a rotational stage is used to measure fields along the round surface and stitch them in order to obtain a complete 3D measurement. The required amount of fields depends on the microscope’s magnification, as well as on the cylinder diameter. However, for small diameters, if the local shape reaches slopes not suitable for the objective under use, the active field of the camera has to be reduced, leading to an increase of the required number of fields to be measured and stitched. In this paper we show a new approach for areal measurements of cylindrical surfaces that uses a rotational stage in combination with a slit projection confocal arrangement and a highspeed camera.

An unrolled confocal image of the cylinder surface is built by rotating the sample and calculating the confocal intensity in the centre of the slit using a gradient algorithm. A set of 360º confocal images can be obtained at different heights of the sample relative to the sensor and used to calculate an unrolled areal measure of the cylinder.

This method has several advantages over the conventional one such as no stitching required, or reduced measurement time. In addition, the result shows less residual flatness error since the surface lies flat in the measurement direction in comparison to field measures where the highest slope regions will show field distortion and non-constant sampling. We have also studied the influence on the areal measurements of wobble and run-out introduced by the clamping mechanism and the rotational axis.