DRUG-ELUTING STENTS

Drug-eluting stents (DES) are coronary or peripheral stents in which a drug-eluting polymer coating is applied to improve the device’s performance when implanted.

When arriving at the coating station, the stents have already gone through dimensional and visual inspection, so the inspection of coated stents is focused on quantifying the amount of drug that has been embedded on each stent and on visually inspecting the coating integrity.

The traditional method for coating process control relies on a weight comparison of the stent before and after the coating process, assuming a homogeneous deployment of the coating. While this method gives an estimation of the amount of coating added to each stent, most coating processes cannot guarantee the homogeneity of the coating and this measurement method becomes unreliable.

Accurate inspection of coating thickness and distribution

Sensofar Medical has developed a new method for accurately mapping the coating thickness on the stents to control the coating process and guarantee that the coating is evenly distributed. In combination with automated visual inspection — focused on coating integrity defects —, our Q six and Q vix inspection systems become the perfect tools for automating drug-eluting stent inspection in production.

The versatility of our systems makes them also great tools for process development and for the optimization of the coating process.

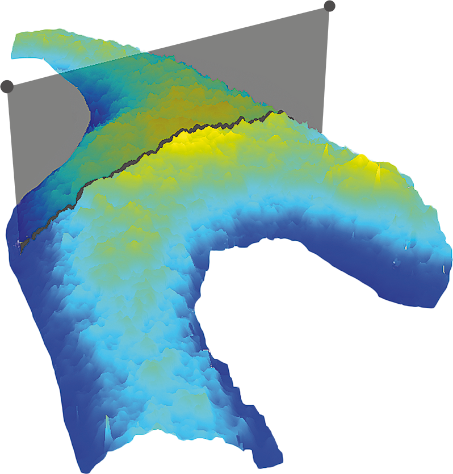

Coating thickness measurement

The technology embedded in our inspection systems enables a non-destructive measurement of optically transparent coatings in the stents.

With a vertical resolution in the nanometric scale, this 3D measurement technique measures the thickness of drug-eluting coatings in a matter of seconds.

This technology combined with the positioning advantage of our inspection systems makes the Q six and Q vix the best tools in the market for characterizing the coating process during R&D and process development, in opposition to tedious and destructive SEM measurements.

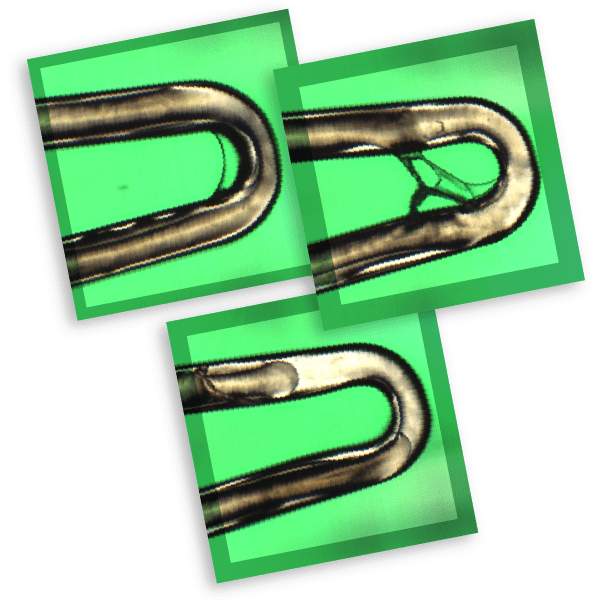

Coating integrity defects

Dedicated detection methods for drug-eluting stents allow the automatic detection of coating integrity defects such as bare areas, coating excess, foreign material, and coating transfer.

The detection of all these manufacturing defects can be adjusted to match the visual standards defined in the inspection specification.

Thanks to the high-quality images obtained it is possible to measure the proportion of the stent that has not been coated.

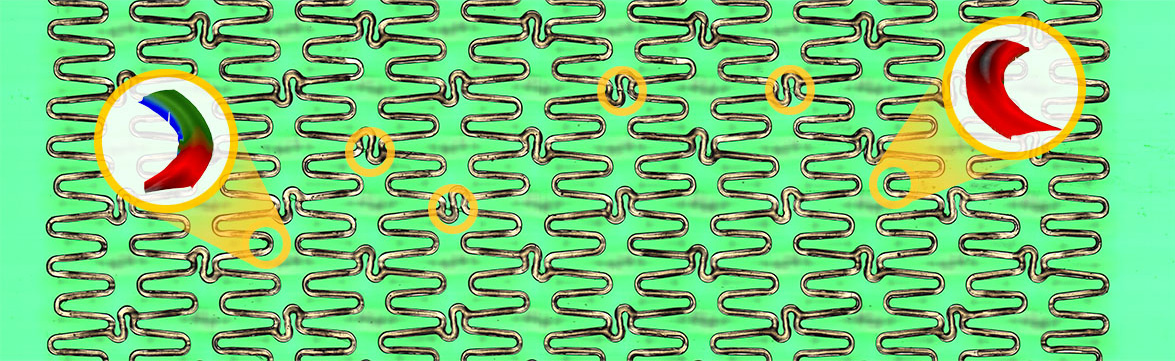

Automatic coating thickness inspection

Moreover, Sensofar Medical has automated the 3D measurements of coating thickness in combination with 2D inspection to provide all the information needed for the inspection of coated stents from a single inspection program.

The powerful software solution developed by Sensofar Medical can locate any coating integrity defect in the stent, measuring the portion of the stent that has been coated, and providing an accurate measurement of the coating thickness in the locations defined, and all of this within seconds.