Measurements for femtosecond laser micro-milling and functional texturing

Microrelleus SLis a company established in 1983. They specialize in laser texturing services (functional and design), laser micro milling and industrial engraving for molds, tools and pieces. In 2016 Microrelleus SL became world pioneers in using a femtosecond laser machine in 5 axis to service their customers. They also use nanosecond lasers for machining in 5 axis, milling machines and die-sinking EDM.

Transparent materials such as glass or PMMA were imaged as well due to Sensofar’s unique new technology called Confocal Fusion that combines Confocal and Focus Variation techniques

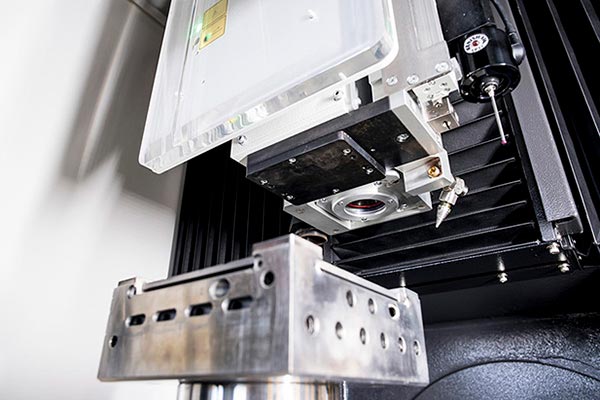

Femtosecond laser is an ultra-short pulse duration laser. Until 2016, it was not possible to integrate a femtosecond laser onto a 5 axis machine. The Swiss group Georg Fischer first achieved this in 2016 thus becoming world pioneers in this technology. This development ushered in a new range of possibilities for manufacturing processes.

With an ultra-short pulse duration laser there are 2 main advantages in comparison to conventional technologies and/or other lasers:

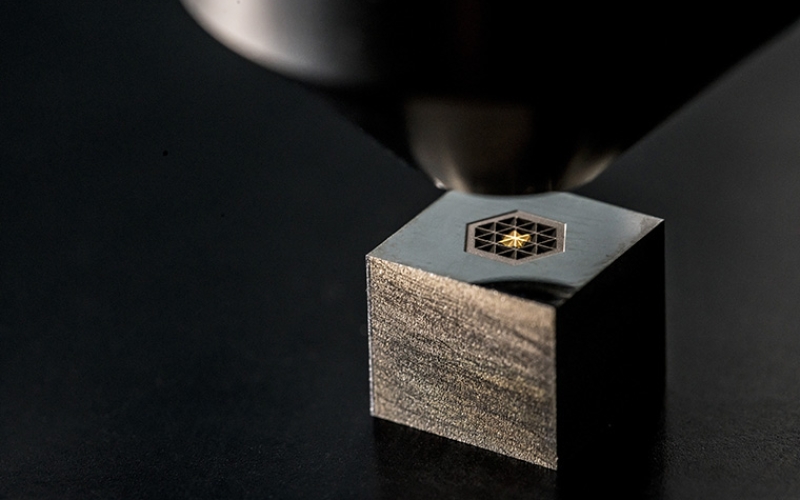

(1) Burr-free micro-milling. There are virtually no thermal effects over the part. The result is a clean and sharp micro-milling, with very sharp edges and high quality surface finishing.

(2) Being a “cold laser” we can engrave over any material: sapphires, plastic, glass, ceramics, aluminum, Steel, etc.

It is optimal technology to use on micro-milling and functional texturing. In 2016, when Microrelleus invested in a femtosecond laser machine with five axis, the measurement requirements had changed. They needed a technology to analyze and measure at the micro and nano-scale for functional texturing. Everything needed to be performed quickly with high accuracy.

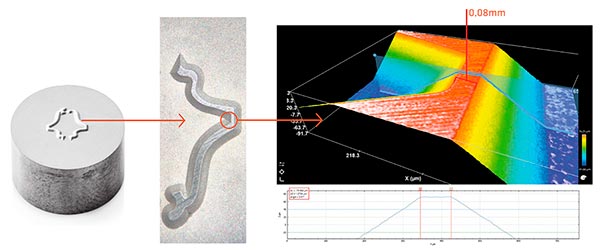

Laser Micro-Milling

This technology is optimal for manufacturing microcavities in mold, microfluidic channels, micro-milling for tempered steel tool or hard metal tool, etc. Using Sensofar’s technology with the 5X and 20X objectives, we were able to check each and every micro-milling project quickly and efficiently with easy to use and operate acquisition and analysis software.

Transparent materials such as glass or PMMA were imaged as well due to Sensofar’s unique capability to combine Confocal and Focus Variation techniques. This new technology is called Confocal Fusion and it merges the information from both technologies into the same topography without compromising acquisition time. Sensofar’s software algorithms are optimized to choose the best acquisition data for each pixel. Thus, it is possible to measure high slope angles with a low magnification objective on highly reflective surfaces in confocal mode, which are common features found on laser textured surfaces.

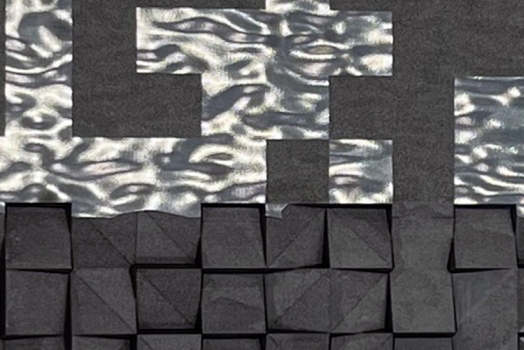

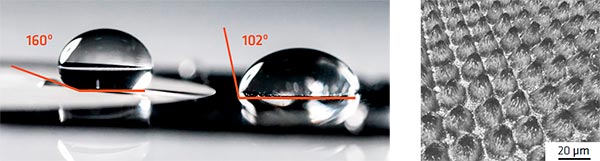

Functional Texturing

Functional texture means adding functionality to the part because of the micro or nano structures created over the material or over the mold of the plastic part. That functionality can be: super hydrophobicity, superhydrophilicity, antibacterial, friction reduction, light diffraction, etc. This is a new and complex process, and we have to be ensure the sizes are perfect when we create the shape, both at the micro and nano scale.

Using Sensofar’s profiler in confocal mode with 100X magnification we are able to analyze nano structures over micro structures because of Sensofar’s outstanding lateral resolution. That is something which we were not able to achieve using other manufacturer’s focus variation microscopes which is a critical requirement for optimal texture functionality.

Sensofar’s confocal and focus variation technologies are an effective combination of techniques to analyse micro-milling and functional texturing over any material, both in the micro and nano scale.

We are able to obtain fast and non-destructive measurements to assure the following:

1) Micro-millings are delivered within the correct tolerance.

2) Functional texturing will work properly based on the created texture