Roughness characterization of Virgo IMC instrumented baffle

Laia Cardiel

The Institut de Física d’Altes Energies (IFAE) is a consortium of the Generalitat de Catalunya and the Universitat Autònoma de Barcelona (UAB) created in 1991. IFAE conducts theoretical and experimental research on the frontier of fundamental physics and in various areas of applied physics, such as medical imaging and quantum computing. In 2019, IFAE initiated a long-term experimental involvement in the Virgo ground-based Fabry- Perot interferometer (Cascina, Italy), with an emphasis on studying fundamental physics using GWs.

“Sensofar was chosen to perform these measurements for their expertise and accessibility.”

Gravitational waves are waves in the space-time fabric. When significant cosmic events like supernova explosions or interactions between black holes occur, the generated gravitational waves are detectable here on Earth. After 50 years of scientific research and technological developments, it has been possible to sense gravitational waves.

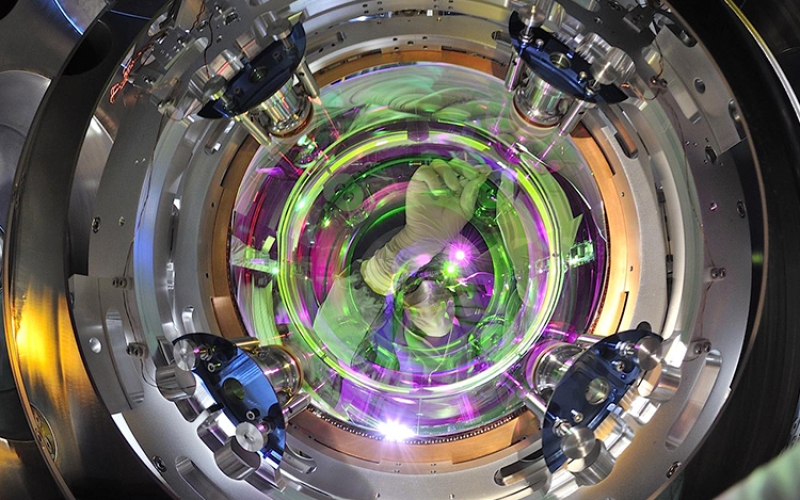

The Advanced Virgo is a gigantic Michelson interferometer capable of detecting them (Figure 1). It has two perpendicular arms 3 km long, suspended mirrors, and other necessary instrumentation to form an interferometer. The gravitational waves modify the optical paths of the beams because of the movement of the suspended mirrors. The optical paths are then modified, resulting in an interference pattern.

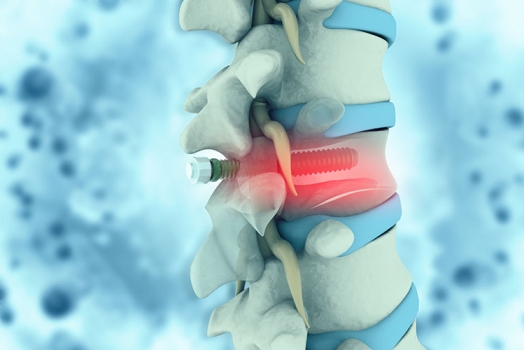

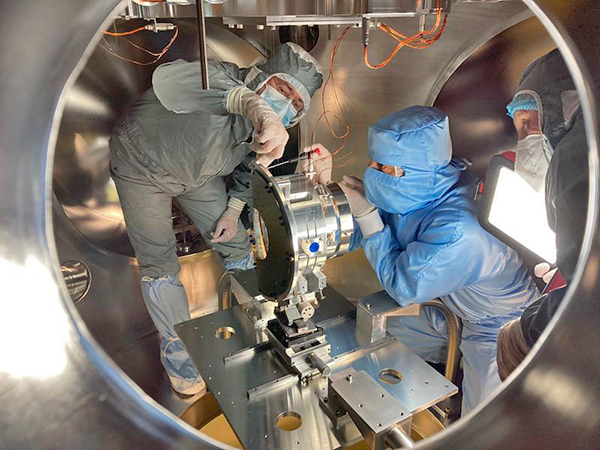

The Institut de Física d’Altes Energies (IFAE) has developed a novel instrumented baffle for the Advanced Virgo. This baffle has been installed in front of the end mirror of the input mode cleaner (IMC) cavity (Figure 2). Its purpose is to absorb stray light reaching its surface. A small fraction that is not absorbed is scattered toward the walls of the IMC tower. Roughness on the mirror surface will result in unpredictable light scattering in unknown directions. If this light recombines with the main beam, it might fake a gravitational way signal.

Determination of surface polishing quality of the instrumented baffles

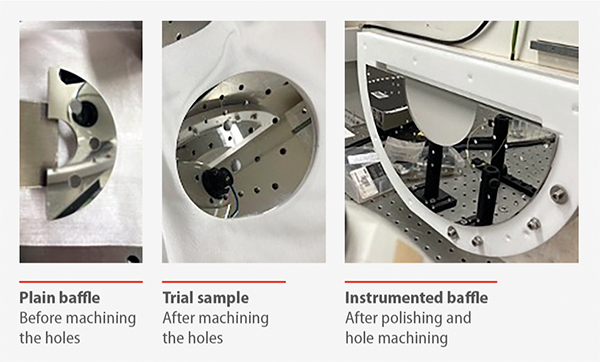

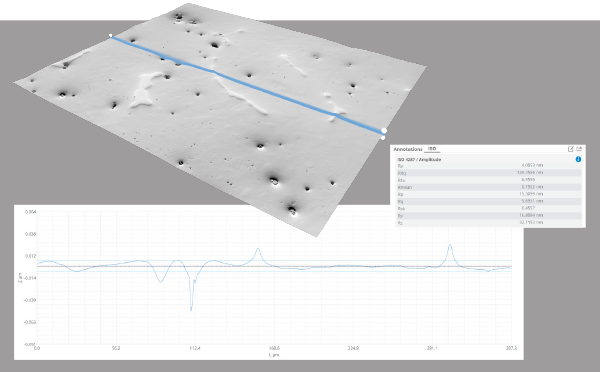

At IFAE, the S neox optical profiler was used to determine the roughness of the polished stainless steel used to build the instrumented baffle. Specifically, measurements were performed after different surface treatments, like polishing and machining of holes (Figure 3).

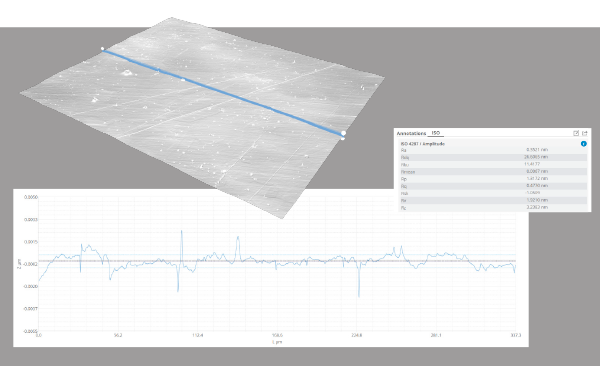

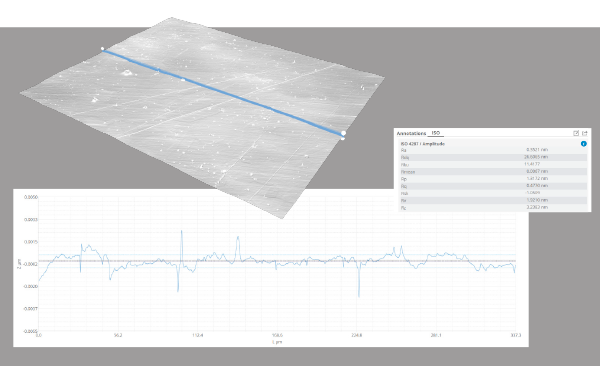

The requirements on resolution and repeatability for measuring the samples only matched with Phase Shifting Interferometry (PSI), one of the modes of interferometry available in the S neox. This optical technique has an extremely low measurement noise, down to a tenth of an Armstrong. That was ideal for the ultra-smooth surfaces analyzed, which had a Ra below 10 nm (Figure 4).

This characterization gave information on how each surface process affected the roughness values and, consequentially, the scattering properties. Regarding that, to be installed in the Virgo IMC the average roughness of the baffle had to be less than Ra= 0.0069 μm. The instrumented baffle complied with the requirement.

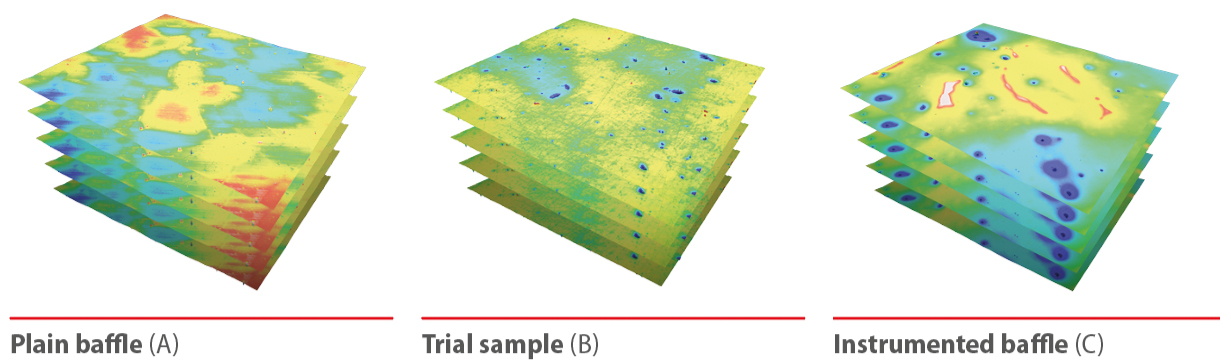

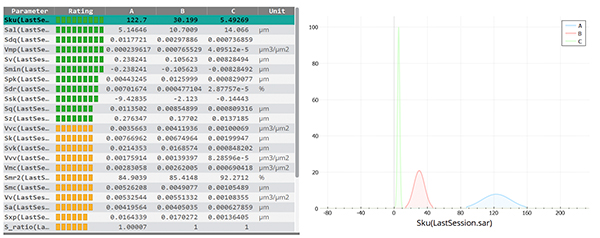

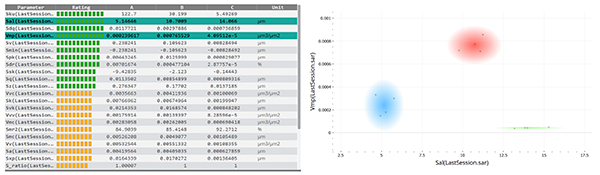

Additionally, areal parameters were also explored for future studies. SensoPRO software makes it easy to find roughness parameters that distinguish different surfaces. Therefore, the three datasets were simultaneously analyzed, and roughness parameters were calculated following ISO 25178. As a result, Figure 5 shows the potential roughness parameters that can differentiate the surfaces (green rating).

Additionally, SensoPRO can display the way two parameters are combined to form a scatter plot to see possible correlations (Figure 6).

Thanks to the S neox, the polishing technique could be certified: the baffle fulfilled the required average roughness of Ra = 0.0069 μm. This, together with a total integrated scattering between 500 and 800 ppm, qualified it to be installed in the Virgo IMC.