Non-destructive characterization of membrane photonic crystal devices

EPFLThe Laboratory for Physics of Nanostructures (LPN) belongs to the Institute of Physics (IPYS) at the Ecole Polytechnique Fédérale de Lausanne (EPFL), one of the leading Swiss technical universities. Our main study is photonic nano-devices, based on the integration of position- and energy-controlled semiconductor quantum dots (QDs) with photonic crystal (PhC) optical cavities and waveguides (WGs).

The S neox provides up to 4 different light sources (red, green, blue and white), which is particularly relevant in this study

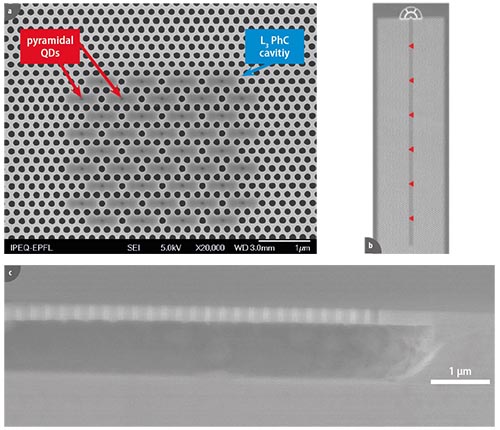

The study is based on the optical properties of QDs that are embedded in PhC cavities (Figure 1a), leading to enhanced emission (the Purcell effect), or in WGs (Figure 1b), producing photon multiplexing devices. A typical device is fabricated from a multi-layer GaAs/Al0.7Ga0.3As/GaAs epitaxially grown stack, where the top 250 nm thick GaAs layer contains the active part of the device, and the 1 µm Al0.7Ga0.3As sacrificial layer is eventually etched away to produce a floating membrane device (Figure 1c).

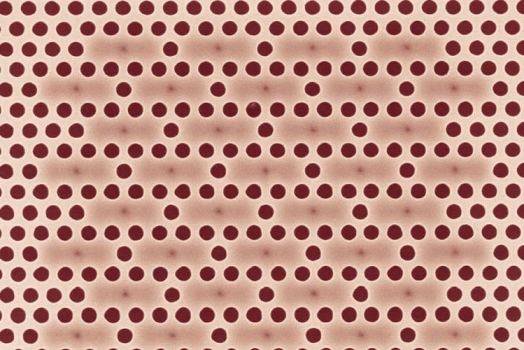

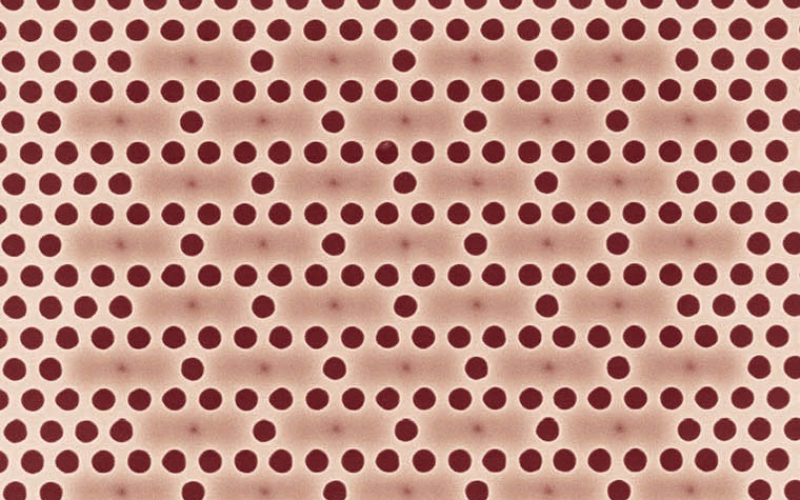

This membrane contains one or several 20 nm In0.3Ga0.7As QDs in specific positions, and an etched PhC structure (large array of 100 nm holes, with several holes missing in a specific configuration), precisely aligned with the QDs. These devices require accuracies of 1-20 nm in several processing steps, so they all involve high-performance electron-beam lithography and plasma (ICP) etching. The crucial final step is the membrane release, involving wet etching of the sacrificial layer. Since at this stage there is no possibility to look at a cross-section of the samples, top-view Optical Microscopy and Scanning Electron Microscopy (SEM) are the only possible tools to characterize the PhC structures.

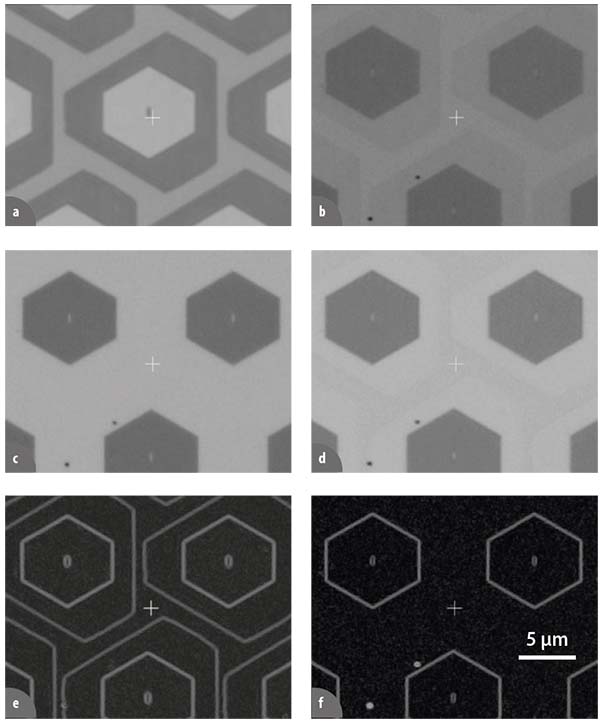

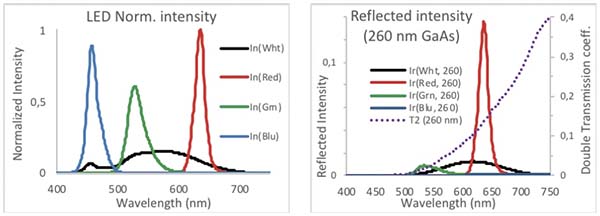

In this study, the S neox was used. The S neox provides up to 4 different light sources (red, green, blue and white), which is particularly relevant in this study as the use of 2D brightfield high-magnification imaging with a red light source enables us to probe the features under the membrane that are otherwise invisible. The purpose of this study is the high-precision (sub-μm) non-destructive characterization of photonic crystal devices fabricated on thin (250 nm) suspended GaAs membranes.

We observed the floating membrane devices by brightfield microscopy, using the 150X objective (sometimes combined with further image zoom), using the microscope’s four LED light sources. As a first approximation, we always suppose that the observed image reflects the surface feature of the device. However, in some devices, e.g. those containing dielectric layers, light can penetrate the top layer and provide information about the inner parts, which is extremely useful. Therefore, we tried to apply this technique to our floating membrane devices. As is well known, GaAs is opaque at the visible spectral range, due to its gap energy of 1.52 eV (815 nm) at room temperature.

At all shorter wavelengths, the absorption coefficient of GaAs is large and strongly wavelength-dependent:1 1.- J. O. Akinlami and A. O. Ashamu 2013 J. Semicond. 34 032002 it varies by a factor of 5 between the red LED (3.9µm-1 at 630 nm) and the blue LED (20.4µm-1 at 460 nm) used in the Sensofar microscope. However, for the thin membranes (250-260 nm) that we use, there is a good chance of recovering useful information from the bottom part of the device, at least with red light, which is less absorbed by the membrane.

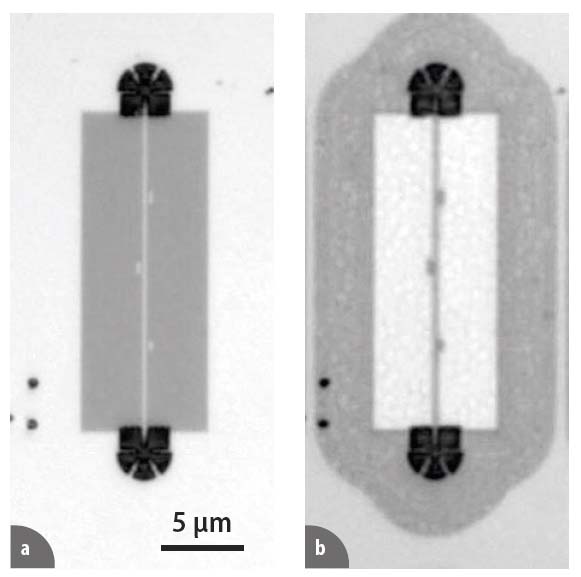

In Figure 4 we show blue (4a) and red (4b) images of a PhC WG device. Similarly to Figure 2a and c, we observe the higher resolution of the blue image, manifested in the sub-micron (0.4×0.8 µm) cavities.

Otherwise, the surface is smooth-looking (except for some isolated defects). If we look at the red-light image of the same area (Figure 4b), we again the device see the whole array as the brightest part of the image, with a gray band around it. It is the image of the etched part under the membrane, visible only in red light. We also observe some granularity of these “internal” surfaces (could be on the bottom part of the membrane or the top part of the substrate), again visible only in this image.

When imaging thin membrane semiconductor devices, we are able to image through the membrane by using red light, while blue light only shows the device’s surface. Using both blue and red brightfield imaging, we could compare the “top” and “inside” images of our photonic devices.

The S neox 3D optical profiler in 2D brightfield imaging mode is very fast, non-destructive, and allows us to image device features that are otherwise not visible. It would be very useful in the characterization of many types of MEMS devices, as the optical absorption of Si shows a similar trend to that of GaAs.